There are so many JAPY clocks still around because Frederic Japy (1749-1812) was one of the founders of the industrialization of not only clocks, but of manufacturing in general. An imaginative inventor of all sorts of machines, he began his career as a watchmaker. At that time, watch and clock parts were manufactured usually by hand by specialized workers in their homes in small communities.

There are so many JAPY clocks still around because Frederic Japy (1749-1812) was one of the founders of the industrialization of not only clocks, but of manufacturing in general. An imaginative inventor of all sorts of machines, he began his career as a watchmaker. At that time, watch and clock parts were manufactured usually by hand by specialized workers in their homes in small communities.

The parts were then collected and mounted into a piece by an 'assembler'. Once the movement was assembled, it was then sent to a 'dresser' who would in turn mount it into a case - be it a small one or an elaborate brass plated mantle clock complete with mythological figures.

Frederic Japy purchased some of few clock making machines in existence, brought them back to his native town of Beaucourt and proceeded to invent new ones in order to standardize the pieces and the quality of the production.

The workers were then regrouped into one location instead of being scattered throughout the countryside and each one was assigned to a specific work post with its own specific machine. Frederic Japy radically changed the way clocks were produced. The sequential production of parts in one location - a manufacturing plant - aided by machines meant that clock parts were made and assembled in about half the time that it had taken previously.

Japy's plant revolutionized manufacturing. Production schedules were now established by the plant owner and not by the local artisan. The number of steps and operations were reduced by half. All parts could be assembled into a finished product on-site instead of the previous sub-assemblies and the machines could be operated by a less-skilled worker.

Japy then imagined other applications (and invented the machines required to produce them) such as the mass production of hardware parts (screws, nails, bolts) and other products - rotating pumps (a model still in use today), locks, and he perfected the creation and baking of enamelware.

In clockmaking - Japy's enamel dials became the standard for the great majority of clock manufacturers for 150 years both in France and abroad. There are few French carriage clocks in existence that do not have Japy enamel dials on them.

Japy's plants continued to produce clocks in many styles and at the higher priced levels. In 1806, he handed the direction of his businesses to his three sons - and it became Japy Frères (Japy Brothers) who in turn diversified the manufacturing to produce coffee grinders, typewriters, enamelware, kitchen utensils, office machines such as the first typewriters, refrigerator pumps, advertising signs and they invented more machines to transform copper and steel wires into elaborate hardware parts.

However, his sons' sons did not inherit the creative and inventive spirit of their fathers and grandfather and by the early 1900's, many of the the businesses were sold off and the manufacturing was dismantled.

A classic Japy Frères clock from the late1890's with the well-known logo and the announcement of having won the 1878 Grand Prize for clockmaking.

A classic Japy Frères clock from the late1890's with the well-known logo and the announcement of having won the 1878 Grand Prize for clockmaking.

ALL Japy clocks - large or small are signed either on the back case and/or stamped on the movement.

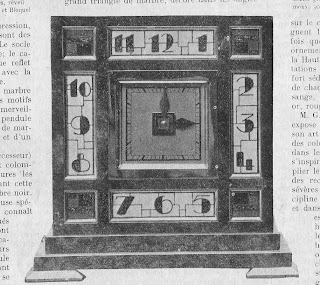

In the 1930's, Japy Frères decided to 'reinvent' themselves to appeal to a wider market and they produced several models with tin casings and in various geometrical styles. Unfortunately they were competing with names such as Jaz and Blangy in that segment of the market and sales were rather limited. As with most French clockmakers, WWII basically decimated them

|

| 1932 ad in la France Horlogère advertising Japy's new line of alarm clocks. |

After the war, the name brand Japy was sold off to another clock manufacturer who mass produced cheap models of alarm and desk clocks.